GRAPHITE PETROLEUM COKE C98.5% 1-5MM

Graphite Petroleum Coke is graphitized at a high temperature of 3000 °C in the Acheson graphitization furnace to form graphitized graphite coke. C 98.5%-99%,S 0.05%max.Size 1-5mm/1-3mm/0-1mm

Graphitized petroleum coke is a kind of high-quality steelmaking and casting recarburizer. It has the advantages of high fixed carbon content, low sulfur content, low nitrogen content, fast absorption speed, good carbonization effect and no dross.Bright alloy has explored in carbon applications in iron and steel for many years,has rich experience ensure partner with best carbon services.

Product Description

GRAPHITE PETROLEIM COKE 98.5% 1-5MM

For casting, cast iron, cast steel and castings will have a requirement for carbon.

Bright Alloy devote to provide iron casting,steel making industry most competitive service and reliable quality in carbon material. Our capacity of various carbon material over 2000 tons monthly,we had long steady cooperation with major steel iron program and foreign iron industry partners with full experiences.

GRAPHITE PETROLEIM COKE USES:

According to the casting application,there are few types:nodular Iron carburizer, gray iron carburizer,cast steel carburizer and special steel carburizer.

- The main technical index difference between gray iron carburizing agent and nodular iron carburizing agent lies in the control of sulfur. The general index requirement is s: ≤ 0.5%;

- The types of carburizing agents for steel casting (steelmaking) are complex.

GRAPHITE PETROLEIM COKE CHEMICAL GRADES:

| Carburant/Carbon Additive | |||||

| Graphilized Petroleum Coke | F.C 99 min% | Ash 0.5% | V.M 0.5% | S 0.05% | 1-5mm |

| Graphilized Petroleum Coke | F.C 98.5 min% | Ash 0.5% | V.M 0.5% | S 0.05% | 1-5mm |

| Calcined Petroleum Coke | F.C 98 min% | Ash 0.5% | V.M 0.5% | S 0.3% | 1-5mm |

Using high quality low sulfur petroleum coke as raw material, produced by graphitization process, it is used for carburization of various electric furnace melting cast steel and cast iron. It has high purity, excellent particle morphology and graphitized hexagonal crystal structure.It not only plays the role of carburization,but also promotes the inoculation and nucleation of cast iron,improves graphite morphology, increases the number of graphite balls, and improves the mechanical properties and processing properties of materials. According to the sulfur content, it can be divided into three levels: low sulfur, medium sulfur and high sulfur.

Chemical specification: fixed carbon: 98-99%, sulfur content: 0.05-0.2%;

Particle size : 1-5mm/1-3mm/0-3mm

Application method:

1. Place the carburizer in the middle and lower part of the electric furnace. That is to say, after a small part of iron charge is placed in the furnace to melt it (or a small amount of hot metal is left on the furnace), the required metal charge is added, and the carburizing agent is fully pressed into the hot metal to make the carburizing agent fully contact with the hot metal.

2. During the absorption period of carburizer, slag removal operation of hot metal should be avoided to prevent carburizer from being taken out of the furnace with slag.

3. It is suggested that the recycled material or pig iron should be added after the carburizing agent is removed.

4. Before the hot metal is discharged from the furnace, a small amount of carburizing agent can be added to the surface of the hot metal for micro carbon transfer, and the carburizing agent can be dissolved and absorbed by eddy current stirring or manual stirring.

5. Increasing silicon and sulfur should be carried out after the absorption of carburizer.

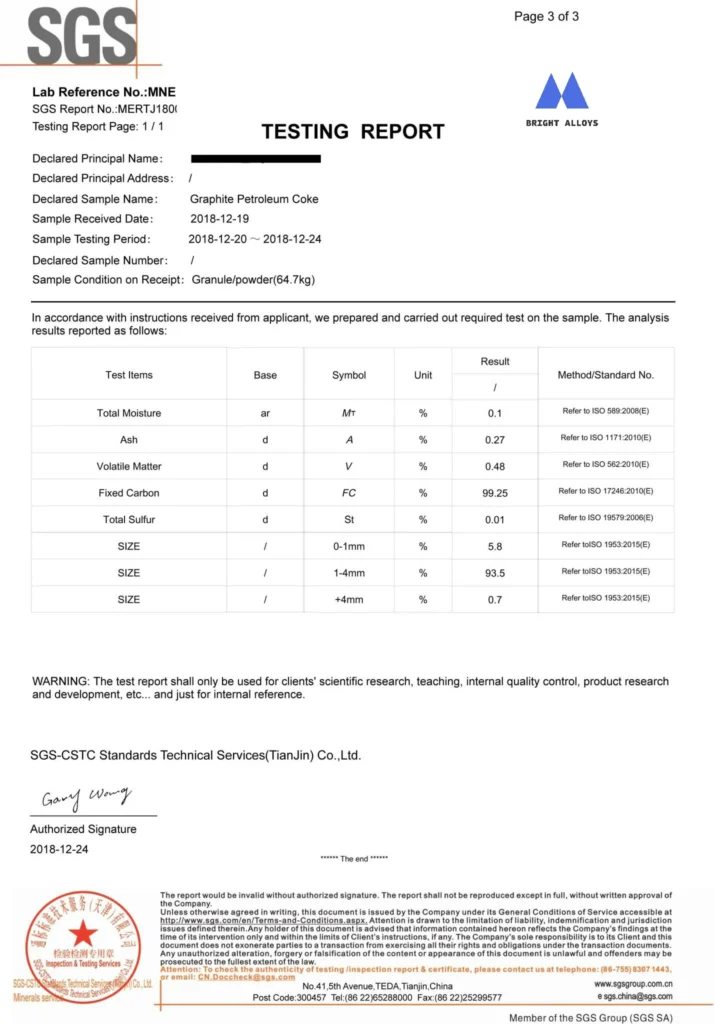

Each batch of goods need to be strictly tested. In terms of quality control system, we have achieved the best system in the same industry. We provide our own test results while supporting any third-party testing requirements, enable helping our partners to ensure the quality of supply in multual ways.

Sizes available:

0-3mm,1-5mm or other size accoriding to customer’s request.

Packing:

25kg/50kg/1mt/1.25mt PP bag

MOQ:1MT

SAMPLE:1KG FREE

PAYMENT TERM:TT/LC

Welcome customer to discuss cooperation with us.Mutual benefit and win-win, long-term stable supply of high-quality low-cost carburizer.

Product Features

| Delivery Time | 7-20 days |

| Minimum order | 1MT |

| Free Sample | Avaialble |

Bright Alloys has 20 years of experience in producing ferroalloys and metals, and has formed industry standard advantages in raw materials, production and logistics in the supply chain.

Bright Alloys has long-term cooperation with many large steel mills and smelters in East and South Asia,its products has exported to over 20 countires around the world.The annual supply of various ferroalloys and metal products exceeds 100,000 tons.

Continuously to provide high-quality ferroalloy and metal products,contribute value to the world metallurgical industry.