FERRO SILICON MAGNESIUM 5-30MM

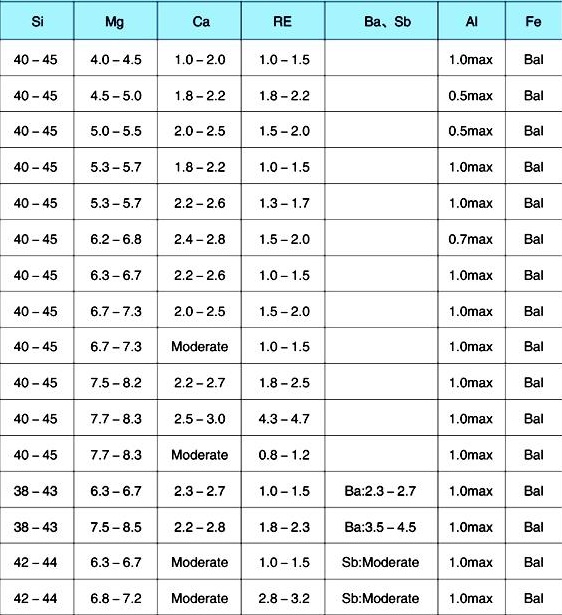

Chemicals:

Mg 4-6% RE 0.5-1.5% Si 44% Ca 1.5-2.5% Al 0.5%

Mg 6-8% RE 0.5-1.5% Si 44% Ca 4.0% Al 0.5%

Mg 5-7% RE 1.5-2.5% Si 44% Ca 2.0-3.0% Al 0.5%

Mg 6-8% RE 1.5-2.5% Si 44% Ca 4.0% Al 0.5%

Mg 7-9% RE 2.5-4.0% Si 44% Ca 2.0-3.5% Al 0.5%

Mg 7-9% RE 6.0-8.0% Si 44% Ca 4.0% Al 0.5%

Mg 7-9% RE 6.0-8.0% Si 44% Ca 4.0% Al 0.5%

Size:5-30mm

Product Description

FERRO SILICON MAGNESIUM 5-30MM

- The content of ferro silicon mangnesium alloy is 4%, 5%, 5.5% which belongs to low magnesium nodularizing agent. Re is between 1% and 2%,thus it is mostly used in medium frequency furnace smelting and spheroidizing treatment of low sulfur molten iron,moreover it has the advantages of slow spheroidization and easy absorption of spheroidized elements.

- 6% and 7% Mg content belongs to medium magnesium series spheroidizing agent, which is mostly used for cupola furnace, electric furnace double melting, or medium frequency furnace melting pearlite cast nodular cast iron castings. According to the wall thickness of casting and sulfur content of molten iron, the appropriate amount of spheroidizing agent is determined, which has wide application range and wide spheroidizing treatment process. Ferro silicon magnesium alloy is suitable for cupola melting with 0.06% – 0.09% sulfur content in molten iron and the addition amount is between 1.6% – 2.0%.

- Low aluminum spheroidizing agent is used in castings which are easy to produce subcutaneous blowhole defects and castings that require aluminum content in molten iron.

The spheroidizing agent produced by pure CE and pure La has the advantages of less inclusions and roundness of graphite ball.

Available Size of ferro silicon magnesium alloy:

2-10mm,5-20mm,5-30mm or other size accoriding to customer’s request.

Packing:

25kg/50kg/1mt/1.25mt PP bag

At present, our total annual production of ferrosilicon magnesium Nodulizer is 4000 tons, the annual production of pipe mold powder is 2500 tons, and the annual production of inoculant reaches 6900 tons. We are marching forward to become a resource-saving and environment-friendly international first-class chemical enterprise.

Bright Alloys has 20 years of experience in producing ferroalloys and metals, and has formed industry standard advantages in raw materials, production and logistics in the supply chain.

Bright Alloys has long-term cooperation with many large steel mills and smelters in East and South Asia,its products has exported to over 20 countires around the world.The annual supply of various ferroalloys and metal products exceeds 100,000 tons.

Continuously to provide high-quality ferroalloy and metal products,contribute value to the world metallurgical industry.