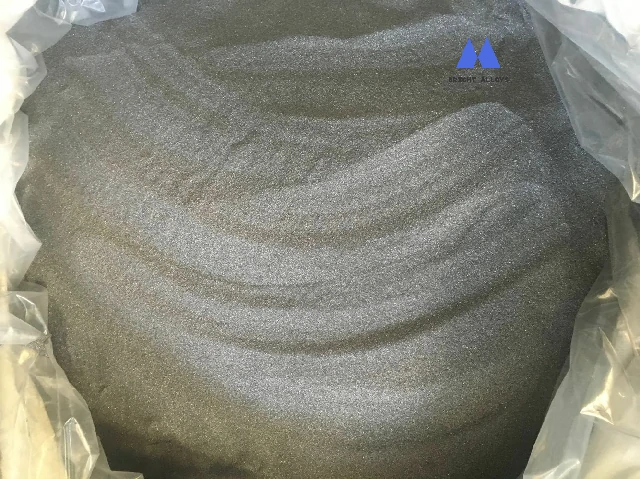

Ferro Silicon Barium 60-70% 0.2-0.8mm

0.2-0.8mm/0-1mm/0-3mm Specifications and size can be customizable.

Ba: 1-2%,Ca 1-2%,Si 60-70%,Al 1-2%

Ba: 4-6%,Ca 1-2%,Si 65-70%,Al 1-2%

Ba: 2% – 5%, CA: 1.5%, Si: 68% – 72%

For gray iron castings, the main function of inoculation is to promote graphitization, reduce the tendency of white mouth, increase the number of eutectic groups, promote the formation of A-type graphite and fine pearlite. For ductile cast iron, the main function of inoculation treatment is to promote the evolution of graphite, improve the inhibition of eutectic permeability, and increase the number of graphite balls per unit area The results show that the microstructure of ductile cast iron is more uniform and the plasticity and toughness of ductile iron are improved.

Product Description

Ferro Silicon Barium 0.2-0.8mm

Ferrosilicon barium inoculant is alloy with mainly iron,silicon and barium elements.It can promote graphitization, reduce the tendency of white mouth, and improve the morphology and distribution of graphite.

Common specifications:

Ba: 1-2%,Ca 1-2%,Si 60-70%,Al 1-2%

Ba: 4-6%,Ca 1-2%,Si 65-70%,Al 1-2%

Ba: 2% – 5%, CA: 1.5%, Si: 68% – 72%

The main functions of ferro silicon barium inoculant:

1. It can increase graphitization core and refine graphite, promote A-type graphite in gray iron castings and improve strength. For nodular iron castings, graphite in nodular iron can be fine and round, and spheroidizing grade can be improved.

2. It can effectively reduce the undercooling degree of hot metal, promote the precipitation of graphite, significantly reduce the tendency of chill, reduce the relative hardness, and improve the machinability of castings.

3. The anti fading ability is strong. The anti fading time is twice as long as that of 75 Si. The addition amount of FeSiBa inoculant is less than half of 75 FeSi inoculant, and the associated spheroidizing degradation is prevented.

4. The sensitivity of wall thickness is small, which can improve the uniformity of section and reduce the tendency of shrinkage porosity.

5. The chemical composition is stable, the processing granularity is uniform, and the deviation of composition and quality is small.

6. The melting point is low (below 1300 ℃), which is easy to absorb and melt during inoculation, and there is very little scum.

Main Sizes and usage:

0-3mm,0.2-0.8mm,3-8mm,1-3mm or other size accoriding to customer’s request.

0-0.25mm: for in mold inoculation (more accurate and more efficient)

0.2-1 mm: for inoculation with current (the control of inoculation amount is more accurate)

1-3mm and 3-8mm are used for in ladle inoculation (the incubation time must be controlled above 70% of tapping time)

Packing of ferrosilicon barium inoculant:

25kg/50kg/1mt/1.25mt PP bag

After more than ten years of development,our company has developed into a professional and diversified alloy service enterprise integrating scientific research, production and sales.

At present, our total annual production of Nodulizer is 4000 tons, the annual production of pipe mold powder is 2500 tons, and the annual production of inoculant reaches 6900 tons. We are marching forward to become a resource-saving and environment-friendly international first-class chemical enterprise.

MOQ:1MT

SAMPLE:1KG FREE

PAYMENT TERM:TT/LC

Product Features

| Delivery Time | 7-20 days |

| Minimum order | 1MT |

| Free Sample | Avaialble |

Bright Alloys has 20 years of experience in producing ferroalloys and metals, and has formed industry standard advantages in raw materials, production and logistics in the supply chain.

Bright Alloys has long-term cooperation with many large steel mills and smelters in East and South Asia,its products has exported to over 20 countires around the world.The annual supply of various ferroalloys and metal products exceeds 100,000 tons.

Continuously to provide high-quality ferroalloy and metal products,contribute value to the world metallurgical industry.